Research and Development

Forward-looking mobility solutions with brand-defining products and services would be unthinkable without technological innovations. This makes our research and development work essential for sustainably increasing the value of the Company.

Together with our Group brands, we have formulated a strategy for networking development activities across the Group and launched numerous initiatives based on our future program TOGETHER – Strategy 2025. At the heart of this is an efficient, cross-brand development alliance characterized by a close network of experts, collaboration on an equal footing, an innovative working environment and the pooling of development activities. With this alliance, we aim to make use of synergy effects across the Group and act as a role model for the environment, safety and integrity. The alliance is playing a major part in the Volkswagen Group’s transformation into a leading provider of sustainable mobility and helping to make the Group fit for the future.

Based on this strategic focus, we concentrated in the reporting year on continuing to develop promising mobility solutions, establishing technological expertise to strengthen our competitiveness, expanding our range of products and services and improving the functionality, quality, safety and environmental compatibility of our products and services.

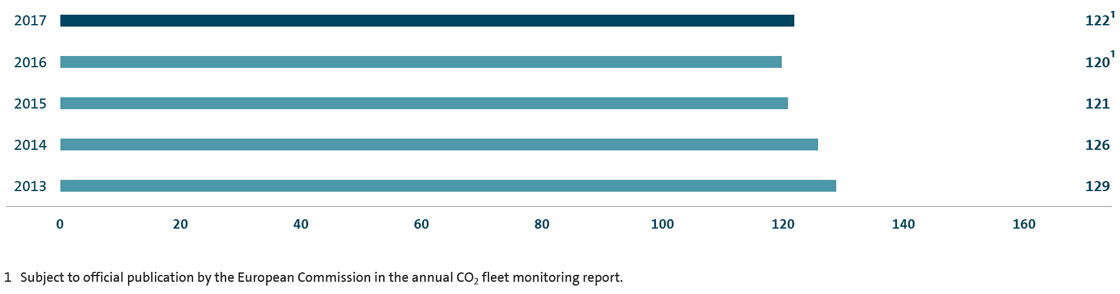

CO2 EMISSIONS OF THE VOLKSWAGEN GROUP’S EUROPEAN (EU28) NEW PASSENGER CAR FLEET

in grams per kilometer

Fuel and drivetrain strategy

The Volkswagen Group’s new passenger car fleet in the EU (excluding Lamborghini and Bentley) emitted an average of 122 g CO2/km1 in the reporting period and was thus well below the 2017 European limit of 130 g CO2/km. The small year-on-year increase is mainly attributable to the new measurement techniques to be applied and the decline in the proportion of diesel vehicles included in deliveries. As small-volume manufacturers, the Lamborghini and Bentley brands each have an independent fleet for the purposes of the European CO2 legislation; Bentley complied with its individual target, Lamborghini was slightly above its target.

As part of a Group-wide initiative – and with a view to the legal regulations on emissions – we are currently developing a forward-looking vehicle and drivetrain portfolio: to achieve our goal of sustainable mobility, we have set ourselves the objective of increasing drive system efficiency with each new model generation – irrespective of whether the means of propulsion is a combustion engine, a hybrid, a plug-in hybrid, a purely electric drive, or a fuel cell drive system.

We anticipate that by as early as 2025, one in four new Volkswagen Group vehicles worldwide will have a purely electric drive; depending on the market development, this could be up to three million electric vehicles a year. The Volkswagen Group has launched a comprehensive electrification offensive in the form of Roadmap E. By 2025, we plan to offer our customers around the world more than 80 new electric models, including some 50 purely battery-driven vehicles and 30 plug-in hybrids. By 2030, the Volkswagen Group aims to electrify its entire model portfolio – from high-volume models to premium vehicles. This will mean offering at least one electric version of each of our approximately 300 models across all Group brands. We are therefore planning to invest more than €20 billion in industrializing e-mobility by 2030, involving, amongst other things, the development of two new electric platforms for vehicles with a range of up to 600 km. Examples include the Volkswagen I.D. family of concept vehicles, the Audi e-tron and Porsche’s Mission E.

To enable sustainable, affordable mobility for as many people as possible, we will continue to offer the full range of drivetrains – from conventional combustion engines to pure electric drive. From today’s perspective, the combustion engine looks set to serve as the broad basis for drive technology in the coming years. In the interest of using resources responsibly, it is therefore essential for combustion engines to be further optimized. We use clean technologies to purify exhaust gases. All our new diesel vehicles are now fitted with an SCR catalyst as standard. From 2018, all our petrol engine cars will have particulate filters.

In addition to electric drives and more efficient combustion engines, renewable, reduced-CO2 fuels (in gas or liquid form) will also play an ever-greater role. We are committed to expanding the natural gas (CNG) infrastructure and are extending our model range accordingly. We are also intensively researching options for producing fuels from renewable electricity, enabling carbon-neutral operation of combustion engines. Projects such as Audi e-gas (power-to-gas) and SEAT’s SMART Green Gas (waste-to-gas) are examples of our commitment in this area.

Last but not least, we are working under Audi’s leadership to make fuel cell technology ready for market.

It is more important to us than ever to rigorously pursue our modular approach. We are reducing the number of individual modules so that we can make a large product portfolio economically viable. Over the long term, we will reduce the number of versions of conventional combustion engines in the Group by more than a third, for example.

This will create capacity for developing and producing new hybrid and electric drives.

Life cycle engineering and recycling

Innovations and new technologies for reducing fuel consumption are not enough on their own to minimize the effect of vehicles on the environment. That is why we examine the entire product life cycle of our vehicles – from the extraction of raw materials to the production of components and the provision of fuel and energy during vehicle use to their final disposal. We identify the stages of the life cycle at which improvements will have the greatest effect and develop appropriate solutions. We call this life cycle engineering. Recycling, for example, is an important means of reducing environmental impact and conserving resources. When developing new vehicles, we therefore pay attention to the recyclability of the required materials, use high-quality recycled material and avoid pollutants. At the end of their lives, our vehicles are 85% recyclable and 95% recoverable. In implementing the Aluminum Closed Loop project in 2017, we created a closed circuit for aluminum beyond our Company boundaries for the first time. Aluminum scrap was returned directly from our press shops to the supplier for reuse in vehicles.